PULA PALA PALAPALA PALAPALA PALAPALA HIGH PRESSURE STEEL PIPE

wehewehe

OD:6-720MM

WT:0.5-120MM

Ka lōʻihi: 3-16M

Hoʻohana: Petroleum, ʻEnekinia Kemika, Uila, Boiler

Kūlana: ASTM A335/A335M, ASTM A213/213M, DIN17175-79, JIS3467-88, GB5310-95

Material:P5,T5,P11,P12,STFA22, P22, T91, T9,WB36

ʻO ka paipu Alloy he ʻano paipu kila maʻemaʻe, ʻoi aku ka kiʻekiʻe o kāna hana ma mua o ka paipu kila maʻemaʻe, no ka mea, ʻoi aku ka nui o Cr o kēia ʻano paipu kila, ʻoi aku ka maikaʻi o kona pale wela, haʻahaʻa haʻahaʻa haʻahaʻa, ʻoi aku ka maikaʻi o ka hoʻokō ʻana i ka corrosion ma mua o nā mea ʻē aʻe. ʻO ka paipu kila, no laila ua hoʻohana nui ʻia ka pipe alloyi ka aila, aerospace, kemika, ka mana uila, ka paila, ka pūʻali koa a me nā ʻoihana ʻē aʻe.

ʻO ka Alloy tube e pili ana i ka hoʻohana ʻana i ka hana extrusion alloy i loko o kahi mea tubular metala, hiki ke pani ʻia i hoʻokahi a ʻoi aku paha i pani ʻia ma nā lua, ka mānoanoa o ka paia a me ka ʻāpana ʻāpana like ʻole, hoʻohana ʻia i nā kaʻa, nā moku, aerospace, aviation, uila, mahiʻai, electro mechanical, home a me nā ʻoihana ʻē aʻe.

Hōʻike

Hoʻohui Kimia

| C, % | Mn, % | P, % | S, % | ʻO, % | Cr, % | Mo, % |

| 0.05-0.15 | 0.30-0.60 | 0.025 ka nui | 0.025 ka nui | 0.50-1.00 | 1.00-1.50 | 0.44-0.65 |

Na Waiwai Mechanical

| Ikaika U'i, MPa | Ka ikaika hua, MPa | Hooloihi, % |

| 415 min | 205 min | 30 min |

Mawaho anawaena & hoomanawanui

|

ASTM A450

| ʻōwili wela | Ka anawaena o waho, mm | Hoʻomanawanui, mm |

| OD≤101.6 | +0.4/-0.8 | ||

| 101.6<OD≤190.5 | +0.4/-1.2 | ||

| 190.5<OD≤228.6 | +0.4/-1.6 | ||

| ASTM A530 & ASTM A335 | NPS | Ka anawaena o waho, ʻīniha | Hoʻomanawanui, mm |

| 1/8≤OD≤1-1/2 | ±0.40 | ||

| 1-1/2<OD≤4 | ±0.79 | ||

| 4<OD≤8 | +1.59/-0.79 | ||

| 8<OD≤12 | +2.38/-0.79 | ||

| OD>12 | ±1% |

ʻO ka mānoanoa o ka pā a me ke ahonui

| ASTM A450 | ʻōwili wela | Ka anawaena o waho, mm | Hoʻomanawanui, % |

| OD≤101.6, WT≤2.4 | +40/-0 | ||

| OD≤101.6, 2.4<WT≤3.8 | +35/-0 | ||

| OD≤101.6, 3.8<WT≤4.6 | +33/-0 | ||

| OD≤101.6, WT>4.6 | +28/-0 | ||

| OD>101.6, 2.4<WT≤3.8 | +35/-0 | ||

| OD>101.6, 3.8<WT≤4.6 | +33/-0 | ||

| OD>101.6, WT>4.6 | +28/-0 | ||

| ASTM A530 | NPS | Ka anawaena o waho, ʻīniha | Hoʻomanawanui, % |

| 1/8≤OD≤2-1/2 | +20.0/-12.5 | ||

| 3≤OD≤18, WT/OD≤5% | +22.5/-12.5 | ||

| 3≤OD≤18, WT/OD>5% | +15.0/-12.5 | ||

| OD≥20, WT/OD≤5% | +22.5/-12.5 | ||

| OD≥20, WT/OD>5% | +15.0/-12.5 |

Kūlana

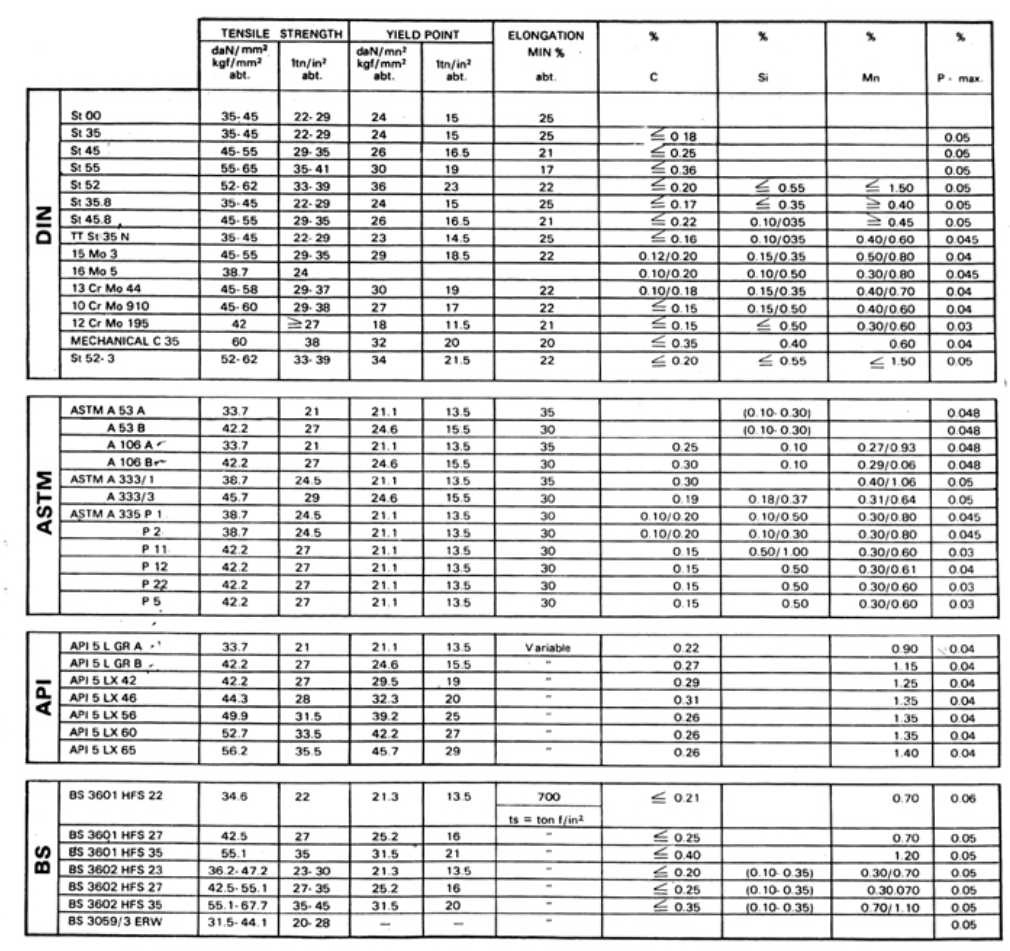

ASTM A335–no ka paipu hao hao ʻole Ferritic Alloy-Steel no ka lawelawe wela wela.

ʻO ASTM A519–no ka ʻili kalapona ʻole a me ka Alloy Steel Mechanical Tubing

ʻO ASTM A213–no ka paila Ferritic Seamless a me Austenitic Alloy-Steel Boiler, Super Heater, a me Heat-Exchange Tubes

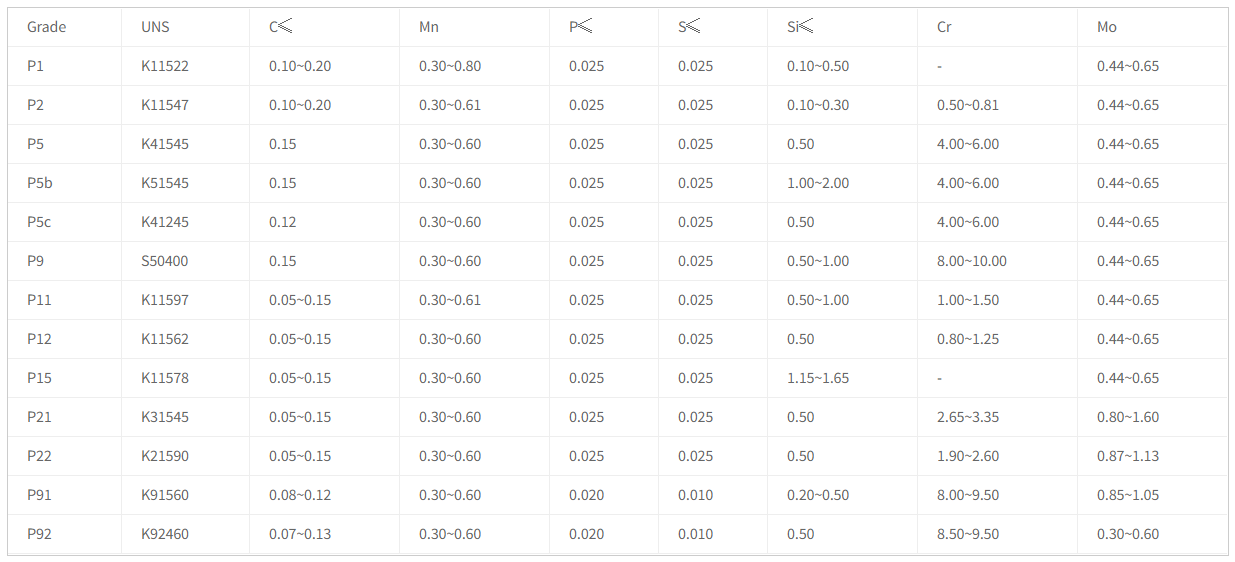

ASTM ASME (S)A-335/(S)A-335M Papa a me ka Hui Kemika

'Ōlelo Aʻo: (S)A335 P91 haku mele 'ē aʻe: V 0.18~0.25;N 0.030~0.070;Ni ≤ 0.40;Al ≤ 0.04 ;Nb 0.06~0.10

(S)A335 P92 hui kemika ʻē aʻe: V 0.15~0.25;N 0.030~0.070;Ni ≤ 0.40;Al ≤ 0.04 ;Nb 0.04~0.09;W 1.5~2.00 ;B 0.001~0.006

Pena & Pena

ʻO ka uhi ʻeleʻele, ka ʻaila/varnish, FBE, 2PE, 3PE, galvanized etc.

Hoʻopili a hoʻouka